Understanding graphene synthesis

Industrial applications of graphene includes the development of batteries, supercapacitors, electrocatalysts, sensors or photodetectors; where materials with functional, flexible, and electrochemically stable properties are required. The production of graphene usually requires processes with high energy and precise control of synthesis conditions. Catalytic or substrate-based techniques for graphene synthesis involve additional process stages for purification or separation. To avoid the use of catalyst or substrates, simplify the control of the process, and improve the yield and productivity, we investigate new substrate-free synthesis methods.

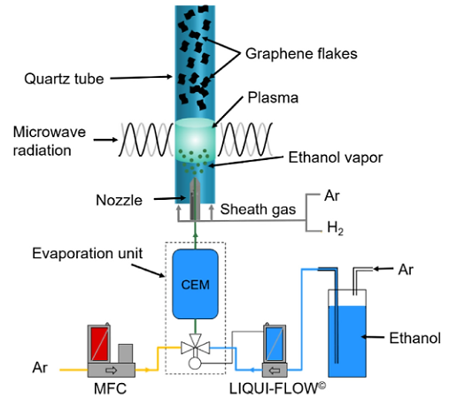

Microwave-assisted gas-phase synthesis of graphene, as a continuous process, is one of the most scalable production routes for obtaining substrate-free graphene flakes for high-quality material. Plasmas provide highly energetic environments by the presence or formation of radicals, ions, and electrons. In a microwave plasma reactor (Figure 1), the precursors enter the coupler region and decompose into smaller reactive fragments, such as C, H, H2, C2, C2H2, and CO. These species then flow into a colder nucleation zone, where they react to form nuclei that rapidly grow into graphene.

However, challenges regarding control of the graphene layer number, defect density, and production yield still remain limiting practical applications, and making it necessary to achieve a better understanding of the mechanism of graphene formation by this process. Further, during microwave gas-phase plasma synthesis, the kinetic competition between soot and graphene formation is another recurring challenge and no detailed information about the mechanisms of nucleation and growth of graphene is available so far.

In our group, the previous challenges are approached initially from the identification of critical steps or processes in the reaction systems, through following and in situ and ex situ diagnostics of the gas-phase reactions; and then from the control of the reaction conditions and therefore of the yield and quality of the flakes. Some of the key steps and processes to follow are sensitive to variables like precursor properties, concentration, which have direct influence on both the growth and decomposition kinetics and the mass and heat transfer profiles. A primary objective is to delineate reactant and process conditions that yield graphene and/or other carbonaceous material, and then perform the following and diagnostics in order to understand the kinetics of early-stage graphene formation.

Characterization of the gas-phase requires understanding the formation kinetics, for which, some diagnostics for in situ characterization are considered [1-3]. Different diagnostics facilitate our understanding of kinetics and transport processes that underlie flake formation and growth. In situ optical diagnostics for particles, temperature, and species concentration are combined with the inline analysis of intermediates via mass spectrometry and ex situ characterization of the products.

References

[1] C.F. López-Cámara, P. Fortugno, M. Asif, S. Musikhin, C. Prindler, H. Wiggers, T. Endres, N. Eaves, K.J. Daun, C. Schulz, Evolution of particle size and morphology in plasma synthesis of few-layer graphene and soot. Combust Flame 258 (2023) 112713. https://doi.org/10.1016/j.combustflame.2023.112713.

[2] P. Fortugno, S. Musikhin, X. Shi, H. Wang, H. Wiggers, C. Schulz, Synthesis of freestanding few-layer graphene in microwave plasma: The role of oxygen. Carbon 186 (2022) 560–73. https://doi.org/10.1016/j.carbon.2021.10.047.

[3] S. Musikhin, P. Fortugno, J.C. Corbin, G.J. Smallwood, T. Dreier, K.J. Daun C. Schulz, Characterization of few-layer graphene aerosols by laser-induced incandescence. Carbon 167 (2020) 870–80. https://doi.org/10.1016/j.carbon.2020.05.052.

Graphene-based composites and heteroaggregates

Gas-phase synthesis represents the cutting edge of modern materials synthesis techniques, enabling quick, scalable, and environmentally safe graphene production with high purity. Graphene-based composites and heterostructures present a compelling prospect for revolutionizing electrochemical energy storage technologies such as Li-ion (LIB) and sodium ion batteries (SIB), owing to their unique structural composition and exceptional properties. In our lab, we generate these structures by integrating gas-phase synthesized graphene with nanoparticles of materials such as Si and Ti, which offer several key advantages that can significantly enhance battery performance [1-3]. Freestanding gas-phase plasma-synthesized few-layer graphene offers higher conductivity and a larger specific surface area compared to reduced graphene oxide. This characteristic further enhances the capacity, rate capability, and stability of graphene-based anode materials for LIBs and SIBs.

Graphene-based heterostructures hold significant promise for advancing battery technology, with implications for diverse applications ranging from portable electronics to electric vehicles and grid energy storage systems. Continued research efforts in this area are poised to address existing battery limitations and drive forward the development of sustainable energy storage solutions.

In our battery laboratory, we study the performance of electrode materials, e.g., by electrochemical cycling and impedance measurements to develop materials that enable improved battery performance.

[1] A. Münzer, L. Xiao, Y.H. Sehlleier, C. Schulz, H. Wiggers, All gas-phase synthesis of graphene: Characterization and its utilization for silicon-based lithium-ion batteries, Electrochimica Acta 272 (2018) 52-59. https://doi.org/10.1016/j.electacta.2018.03.137

[2] A. Al-Kamal, M. Hammad, M. Yusuf Ali, S. Angel, D. Segets, C. Schulz, H. Wiggers, Titania/graphene nanocomposites from scalable gas-phase synthesis for high-capacity and high-stability sodium-ion battery anodes, Nanotechnology 35 (2024)225602. https://doi.org/10.1088/1361-6528/ad2ac7

[3] L. Xiao, M. Schroeder, S. Kluge, A. Balducci, U. Hagemann, C. Schulz, H. Wiggers, Direct self-assembly of Fe2O3/reduced graphene oxide nanocomposite for high-performance lithium-ion battery, Journal of Mater. Chem A 3 (2015) 11566-11574. https://doi.org/10.1039/C5TA02549