Funded Projects

LaufFGL - Laser deposition welding of functional layers from shape memory alloys

Project number: EFRE-20800188

Duration: 02.05.2024 – 31.12.2027

Description

The aim of this project is to integrate an active element into a bolted joint that counteracts temperature-related setting losses and ensures the safety of the bolted joint. For this purpose, a shape memory alloy (SMA) actuator is used, which is minimally and locally introduced into the bolted joint by laser deposition welding (DED-LB/M). As a result, the material is used in a resource-saving and cost-efficient manner, which is of particular interest for the high quantities of fasteners. In particular, chemical (passive) threadlockers, which have a long-term harmful effect on aquatic organisms, could be replaced by the planned compound. The project combines a special material, namely the SMA alloy NiTi, with the DED-LB/M production technology. The process thus represents an energy-efficient and sustainable solution in which an innovative material is combined with an intelligent production process.

This project is a co-operation with Ingpuls GmbH, Bochum, the Chair of Laser Application Technology at the Ruhr-University Bochum, and Schotte Automotive GmbH & Co. KG, Hattingen. At the Chair of Materials Science and Engineering at the University of Duisburg-Essen, the layer-substrate composites to be developed are being examined for their mechanical properties, their friction and wear behaviour, as well as their possible susceptibility to corrosion, as a basis for the joint development of high-performance active connecting elements.

This project is funded by the European Union and the state of North Rhine-Westphalia as part of the ERDF/JTF programme NRW 2021-2027.

Research area: surfacing, friction and wear of coatings, corrosion of dissimilar welded joints

Contact: Prof. Dr.-Ing. Stefanie Hanke

Cooperation partners: Ingpuls GmbH – Experten für FGL, Bochum; Lehrstuhl für Laseranwendungstechnik, Ruhr-Universität Bochum; Schotte Automotive GmbH & Co. KG, Hattingen

Developing methods for in-situ and real-time measurement of surface damage induced by cavitation using electrochemical techniques

Project number: DFG 529857700

Expected duration: 01.01.2024 – 31.12.2026

Description

In-situ real-time detection of cavitation damage has been a challenge for many years. Among the non-invasive techniques, optical inspection may not be possible as relevant surfaces may be covered by cavitation structures or optically not accessible at all. The erosion-enhanced corrosion during cavitation, on the other hand, can be used for real-time in-situ and even non-invasive detection of cavitation damage. Here, electrochemical techniques, especially those that are sensitive to high-speed short-time changes on the surface, should be applied.

In this research project, the effects and interrelations of erosion and corrosion of technical alloys under ultrasonic cavitation and single bubble cavitation will be studied on different time and length scales using various electrochemical techniques. High-speed cameras will be used to reveal details of bubble collapse and correlate them with high-time resolution electrochemical signals from the chronoamperometry technique. Observing open circuit potential (OCP) and applying external anodic and cathodic potentials will reveal the influence of repassivation kinetics, the nature of passive films, and other effects of electrochemical behavior on erosion-corrosion damage. As we use and compare the various electrochemical techniques under different testing conditions (sample size, target alloy, and applied potential), it will be possible to assess and verify the capability of these techniques, especially high-speed chronoamperometry, for measurement of cavitation damage real-time in-situ either non-invasive at free potential or invasive under potentiostatic conditions.

M. Abedini, S. Hanke, F. Reuter, In situ measurement of cavitation damage from single bubble collapse using high-speed chronoamperometry, Ultrasonics Sonochemistry 92 (2023) 106272.

Research area: tribocorrosion, cavitation, electrochemical measurements, high-speed imaging, high-speed chronoamperometry

Contact: Dr. Morteza Abedini

Classification of wear characteristics for lubricated sliding wear based on normal and frictional forces using artificial intelligence

Project number: DFG 525173005

Duration: 01.01.2024 – 30.06.2026

Description

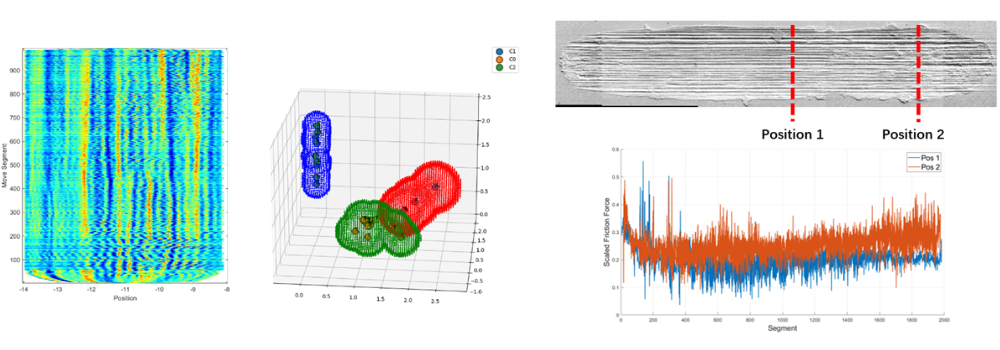

Friction and wear have long been one of the main causes of economic losses in industry. However, due to the complexity of friction systems, modeling and predicting wear behavior remains difficult. Traditional modeling approaches are often based on morphological analysis of worn surfaces and measurement of wear characteristics (mass/volume loss). Artificial intelligence, as a new emerging research method, shows great advantages in coping with complex mapping relationships with multiple variables.

This DFG project aims to establish a mapping relationship between friction forces, normal pressure and wear behavior using AI models. First, the force data recorded in real time is reconstructed based on physical behavior. Subsequently, the analysis is performed on the reconstructed data together with SEM images to investigate the correlation between the force data and the wear morphology. Finally, a suitable AI model is selected and trained to establish the mapping relationship between the force data and the wear behavior.

Compared to the traditional methods, an AI model based on force data provides better generality and enables faster monitoring and evaluation of wear behavior in the future.

Research area: Tribology, wear mechanisms, wear prediction, machine learning, artificial intelligence

Contact: Prof. Dr.-Ing. Stefanie Hanke

Cooperation partner: Dr.-Ing. Philipp Sieberg

Nanoscale interaction of microstructure and tribological damage in additively manufactured high-nitrogen alloy austenites for medical applications

Funding: MERCUR KOOPERATION

Duration: 01.05.2022 – 30.04.2023

Description

High nitrogen alloyed austenitic steels (HNA) have a unique combination of highest strength, toughness and corrosion resistance due to high contents of the elements carbon (C) and nitrogen (N). HNA therefore offer potential for use particularly in medical technology and the hydrogen economy. Processing by metallic 3D printing using powder bed fusion - laser beam (PBF-LB) also enables resource-efficient use of HNA in lightweight construction by replacing austenites of lower strength. In this project, the complex nano- and microstructure formation in PBF-LB, as well as the interaction between microstructure and tribological behavior are investigated using HNA X40MnCrMoN21-18-2. Microstructure formation is traced from the metal powder, through the PBF-LB process and a thermal post-process down to the atomic level. Further, the influence of the PBF-LB microstructure on damage accumulation under sliding wear and cavitation is elucidated. This yields important insights into peculiarities in the behavior of HNA in additively manufactured components.

Optical in-situ analysis of the cavitation damage on technical alloys under repeated single bubbles

Project number: DFG 451715773

Expected duration: 01.04.2021 – 31.03.2024

Description

Cavitation - the formation and collapse of gas bubbles in liquids - can damage even high-strength surfaces in the long term. The resistance of materials to cavitation is typically determined using ultrasonic sonotrodes that generate clouds of bubbles of various sizes. Alternatively, it is possible to use focused laser pulses to create single bubbles that are spatiotemporally precisely reproducible. So far, however, it is unclear how these results can be applied to higher-strength materials.

In this project, the microscopically uncontrolled damage caused by acoustic cavitation is combined with the precisely reproducible load from single bubbles. Series of single bubbles act as a load collective on surfaces of high-strength alloys. By recording the bubble collapse with a high-speed camera and the incremental increase in damage with an integrated light microscope, the process of material damage can be traced in detail. High-resolution ex-situ microscopy then allows identifying the microstructural damage mechanisms. In order to correlate the results on material damage with what is already known in material science, standard tests with a sonotrode are carried out in parallel.

S. Hanke, S.A. Kaiser, Comparison of Damage Mechanisms: Acoustic Cavitation versus Series of Single Laser-Induced Bubbles, Wear, available online 3 February 2021, No. 203641, In Press

Research area: tribology, wear mechanisms, optical diagnostics, image analysis

Contact: Dr.-Ing. Stefanie Hanke

Collaborator: Prof. Dr. Sebastian Kaiser

Deformation and failure mechanisms in austenitic steel under coupled compressive and torsional loading

Project number: DFG 441180620

Duration: 01.10.2020 – 30.09.2023

Description

In practice, components are often exposed to multi-axial mechanical loads, typically occurring as a function of time and reversing. Experimental investigations under such complex load collectives are very time-consuming, so that the mechanisms that lead to plastic deformation and failure of materials under such conditions are only poorly understood. As a result, there is also an uncertainty as to whether common solid-state mechanical failure hypotheses are valid under these conditions.

In this project, the deformation and damage mechanisms in a high nitrogen austenitic steel under superimposed pressure and cyclic torsional loads are experimentally investigated. Influences of the specific load condition on the microstructural mechanisms of strain and damage accumulation are analyzed by high-resolution microscopy. Based on the experimental results, a constitutive model within the framework of crystal plasticity is formulated by the cooperation partner at Ruhr-University Bochum, which reliably describes cyclic plasticity and damage under multiaxial loads on the microstructure level.

Research area: plastic deformation, austenitic steel, damage mechanisms

Contact: Dr.-Ing. Stefanie Hanke

Cooperation Partner: Prof. Dr. Alexander Hartmaier

Influence of Mg and Si Content in Aluminium Alloys on Severe Plastic Deformation Behaviour during Solid-State Coating Deposition using Friction Surfacing

Project number: HA 7834/1-1

Duration: 05.05.2017 – 30.04.2020

Description

Dynamic recrystallization has a major influence on process characteristics and material flow in friction-based solid state joining techniques. In addition to general material properties, a.o. heat capacity and high temperature strength, dynamic microstructural processes, e.g. dislocation movement, grain boundary migration, formation of substructures or precipitation of phases, have a strong effect on the acting flow stresses. Small changes in the content of alloying elements, e.g. in Aluminium alloys, require significant adaptations of the process parameters, which are to date established by empirical or statistical approaches.

In the scope of this project 6 custom-made Aluminium alloys are processed by Friction Surfacing (FS), in cooperation with the Helmholtz-Zentrum Geesthacht. Each of these alloys only differs in its content of Mg or Si, allowing a direct comparison and therewith the investigation of the effects of those alloying elements on the material behaviour. The Si content will be raised up to 17.5 wt%, providing undissolvable hard phases during processing, which will further influence the deformation and recrystallization mechanisms. Besides examining process forces and coating geometry, XRD, EBSD and TEM investigations of the microstructural mechanisms of plastic deformation will be carried out, and correlated with the material behaviour during FS.

Research area: Materials Science, Severe Plastic Deformation

Contact: Dr.-Ing. Stefanie Hanke

Metallurgical mechanisms of cyclic plastic deformation by High Pressure Torsional Fatigue (HPTF)

Program for the Advancement of Excellent Young Researchers (by University Duisburg-Essen)

Duration: 01.08.2017 – 31.12.2018

Description

Plastic deformation of metals and alloys has been used for centuries to modify their properties and increase their strength. In recent times the generation of nanocrystalline microstructures by severe plastic deformation (SPD) has become a topic of high scientific interest. The very high strains achieved by SPD techniques are realized through the superposition of hydrostatic pressure, and lead to recrystallization at low temperatures. Thereby the grain size can be decreased into the nm-scale. Classical SPD techniques are based on monotonic deformation. In the scope of this project it will be investigated, wether the cyclic accumulation of plastic strains can lead to comparable effects. By torsional loading various strains and strain rates will be introduced into the material across the radius of cylindrical samples. Which microstructural mechanisms take place under this kind of loading will be clarified through electron microscopy.

Research area: Materials Science, Severe Plastic Deformation

Contact: Dr.-Ing. Stefanie Hanke

Monitoring and Quantification of Cavitation Corrosion Erosion through Electrochemical Noise Method

DFG – Grants to Support the Initiation of International Collaboration

Project number: 407436768

Duration: 01.06.2018 – 31.08.2018

Description

Cavitation corrosion erosion results from the interaction of mechanical and chemical phenomena, which contributes to material removal from mechanically eroding surfaces exposed in corrosive environments. The synergism between cavitation erosion (mechanical factor) and corrosion (electrochemical factor) during cavitation corrosion erosion can cause an overall material loss greater than the sum of the material loss as it would be produced by each mechanism acting separately. This is the result of effect of corrosion on cavitation erosion as well as the effect of cavitation erosion on corrosion.

In a first step, the possibility of monitoring and quantification of cavitation corrosion erosion using a non-destructive method, i.e., the electrochemical noise technique (ECN) is investigated. A possible application to marine components is of strong interest for future research, aiming at monitoring the material deterioration and developing methods to predict the remaining service life.

In this project, a collaboration between Dr.-Ing. Stefanie Hanke (Materials Science and Engineering, Uni DUE), Dr. Morteza Abedini (Department of Metallurgy and Materials Engineering, University of Kashan, Iran) and Dr. rer.nat. Fabian Reuter (Institute of Ship Technology, Ocean Engineering and Transport Systems, Uni DUE) is initiated.

Research area: Tribology, Corrosion, Cavitation

Contact: Dr.-Ing. Stefanie Hanke

Bionische Werkzeugkonzepte für die schädigungsfreie Bearbeitung von modernen faserverstärkten Hochleistungspolymeren

Project number: Pr-2012-0002

Duration: 01.01.2013 - 31.12.2014

Description

Für die in einem breiten gesellschaftlichen Konsens als notwendig erachtete Reduzierung der CO2‐Emissionen spielt der Leichtbau, vor allem in der Fahrzeug‐ und Luftfahrttechnik, eine zentrale Rolle. Besonders die Verwendung kohlenstofffaserverstärkter Kunststoffe (CFK), die ein geringes Gewicht bei gleichzeitig hoher Festigkeit zeigen, gilt hierfür als geeignetes Mittel. Diesem Vorteil stehen allerdings Nachteile in Bezug auf die Fertigung entgegen. Vor allem die spanende Bearbeitung ist schwierig, weil die Kohlenstofffasern einen starken Verschleiß an den Werkzeugschneiden bewirken, die somit schnell stumpf werden, was zu Schädigungen der CFK bei der Bearbeitung führt. Die Natur zeigt für Probleme dieser Art einen Lösungsansatz: Nagetierzähne schärfen sich selbst nach. Durch geschickte Kombination harter und weicher Bestandteile wird der Schneidenverschleiß nicht vermieden, sondern so gesteuert, dass der Materialverlust nicht zum Abstumpfen, sondern

zum Schärfen der Schneide führt. Dieses Konzept lässt sich auf technische Anwendungen übertragen und wurde für Schneidanwendungen erfolgreich umgesetzt. Im hier beantragten Projekt soll das Konzept auf einen Zerspanprozess übertragen werden. Dazu werden unterschiedliche Schichtkonzepte und Schnittparameter untersucht. Sowohl das Werkzeug als auch das zerspante Material werden werkstoffkundlich eingehend analysiert, um die Werkzeugverschleiß‐ und Werkstoffschädigungsmechanismen zu verstehen und auf dieser Basis den Selbstschärfungseffekt zu optimieren und die Grundlagen für die industrielle Anwendung zu erarbeiten.

Research area: Material Science

Contact: Dipl.-Ing. Priska Stemmer

Erhöhung von Leistungsdichte und Lebensdauer hochbelasteter Funktionsflächen durch spanende Oberflächenkonditionierung

Project number: Pr-2011-0002

Duration: 01.01.2012 - 31.12.2013

Description

Die heutigen Wettbewerbsbedingungen und politischen Vorgaben fordern ein ständig höheres technisches Niveau von Produkten bei stetig steigenden Beanspruchungen und erhöhter Verfügbarkeit. Dieses führtdazu, dass tribotechnische Systeme, die früher unter hydrodynamischen oder elastohydrodynamischen Bedingungen betrieben wurden, zunehmend unter reibungs- und verschleißintensiveren Misch- und Grenzreibungsbedingungen eingesetzt werden. Dies gilt u.A. für Motorkomponenten im Ventiltrieb, Windkraftgetriebe und Hartgewebeimplantate bei Verschleißraten unterhalb von 3 nm/h im Bereich des sog.

(ultra-mild wear). Die niedrige Verschleißrate hängt dabei im Wesentlichen von der Ausbildung einer stabilen oberflächigen Grenzschicht - dem sog. Tribomaterial - ab, das strukturell und chemisch gegenüber dem Grundwerkstoff verändert ist. Tribomaterial wird in der Einlaufphase erzeugt. Dabei treten Verschleißraten auf, die drei bis sechs Größenordnungen größer sind als in der daran anschließenden stationären Phase, in der sich das Tribomaterial aufgrund seiner nanoskaligen Struktur ständig regeneriert. In diesem Projekt geht es darum, den Einlauf zu verkürzen oder ganz zu unterdrücken und eine durch eine gezielte spanende Endbearbeitung entsprechend bzgl. Topographie und Tribomaterial optimierte Oberfläche vorliegen zu

haben. Das stabile Tribomaterial ergäbe sich damit nicht mehr zufällig im Einsatz sondern würde gezielt werkstoff- und belastungsabhängig in der Endfertigung erzeugt. Die genauen Wechselwirkungen aller beteiligten Elemente sind bis heute nicht geklärt. Deshalb soll wissenschaftlich untersucht werden, welche Parameter für die Induktion (hier: spanende Endfertigung) und welche Mechanismen für die Regeneration (hier: Gleitverschleiß unter „ultra-mild wear“ Bedingungen) der Grenzschichten an drei ausgewählten metallischen Werkstoffen (Perlit, Martensit, Austenit) aus den Bereichen Automobil-, Energie- und

Medizintechnik maßgeblich sind.

Research area: Material Science

Contact: Dipl.-Ing. Priska Stemmer (Mikroskopy); Dipl.-Ing. Daniel Stickel (Wear experiments)

Strutkturbildung und Selbstregenerationsmechanismen der triboinduzierten Randschicht von Metallen

– Experiment und Simulation

Project number: FI 451/14-1

Duration: 01.07.2011 - 30.06.2013

Description

Metallische Werkstoffe bilden unter günstiger Reibbelastung eine charakteristische oberflächennahe Zone aus. Jüngste Ergebnisse zeigen, dass durch die Bildung dieser Zone Reibung und Verschleiß deutlich sinken. Das wesentliche Ziel des Vorhabens besteht darin, das tribologische Verhalten (Reibung und Verschleiß) metallischer Werkstoffe bei Gleitverschleiß und Grenz‐ und Mischreibung über den Reibvorgang zu optimieren. Dies kann erreicht werden, wenn es gelingt, während der Reibbelastung die Eigenschaften des tribologischen dritten Körpers einzustellen. Um dieses Ziel zu erreichen ist

ein grundlegendes, mechanismen‐basiertes Verständnis der Bildung oberflächennaher Veränderungen für verschiedene Werkstoffe nötig, was in diesem Projekt erstmalig durch Laborversuche und Computersimulation mit identischen Tribosystemen ermöglicht werden soll.

Research area: Material Science

Contact: Dipl.-Ing. Priska Stemmer

Einladungen von ost- und mitteleuropäischen Wissenschaftlern nach Deutschland

Project: publicly funded research project

Project number: DFG 436 POL 17/10/04, DFG 436 POL 17/02/03, DFG 436 POL 17/06/02, DFG 436 POL 17/01/01, DFG 436 POL 17/12/00, DFG 436 POL 17/02/06

Description

In Zusammenarbeit mit dem Institute of Materials Science and Applied Mechanics der Technischen Universität Wroclaw in Polen (Prof. Dr. Wlodzimierz Dudzinski werden mehrere Projekte aus dem Bereich der Transmissions-Elektronenmikroskopie bearbeitet. Prof. Dudzinski ist in jedem Jahr für mehrere Wochen in Duisburg zu Gast und steht den Wissenschaftlern und Studierenden mit seinem Fachwissen zur Verfügung. In diesem Zusammenhang werden zurzeit Untersuchungen zu Verformungsstrukturen in hochstickstoffhaltigen Stählen, an verschlissenen Oberflächen von explantierten Hüftgelenk - Prothesen und an magnetischen Werkstoffen nach Verschleißbeanspruchung durchgeführt. Darüber hinaus findet ein Austausch von Studierenden beider Universitäten statt.

Research area: Material Science

Contact: Priv.-Doz. Dr.Ing.habil. Sabine Weiß

Wissenschaftliche Zusammenarbeit mit Ägypten

Project: publicly funded research project

Project number: 445 AGY 112/9/06

Description

Im Rahmen einer Kooperation zwischen der Universität Duisburg-Essen, Werkstofftechnik und dem Central Metallurgical Research and Development Institute (CMRDI) Cairo, Egypt werden mehrere Projekte aus dem Bereich der Mikrostrukturentwicklung bearbeitet:

Untersuchungen auf dem Gebiet des Hochtemperaturkriechens von ausscheidungsgehärteten Stählen und Nickelbasis-Superlegierungen.

Projekt zur Schwellbeanspruchung von Eisen- und Kobaltbasislegierungen mit unterschiedlichen Stapelfehlerenergien: Grundlagenforschung zur Ermittlung des Einflusses der Mikrostruktur auf das Verformungsverhalten bei schwellender zyklischer Belastung.

Research Area: Material Science

Contact: Priv.-Doz. Dr.Ing.habil. Sabine Weiß

Fatigue behaviour of Cu-based single and stranded wires

Associate partner: Deutsches Kupferinstitut Berufsverband e.V. & International Copper Association

Description

Dimensioning of technical components in order to reach endurance strength makes the use of mechanical values necessary. For many technical materials this values can be found in standards or guidelines as minimum or standard values. The determination of mechanical values for Cu-base materials in thin single wire or stranded wire shape under cycling loading is the aim of this project. The test and investigation methods for this material shape may differ compared to usually known since the microstructure is oligocrystalline due to the grain size/wire diameter ratio in this small profiles. Here the use of adequate or adapted investigation methods is necessary. Beside the wire surface and stranded wire structure the anisotropic properties need to be considered. In a first approach the mechanical behaviour of single wire samples is investigated and statistically secured under bending load.

Research area: Material Science

Contact: Dipl.-Ing. Michael Schymura

Rührreibschweißanlagen für das Fügen großflächiger Stahlstrukturen - FSW-Steel

Verbundprojekt im Rahmen des „Zentrales Innovationsprogramm Mittelstand (ZIM)"

Teilprojekt: Entwicklung leistungsfähiger Werkzeuge für das Rührreibschweißen von Stahl

Project number: VP2095003PK9

Duration: 01.12.2009 - 31.10.2011

Partner: SLV Berlin-Brandenburg, Ingenieurtechnik und Maschinenbau GmbH, Lippold Hydraulik und Wälzlager GmbH, Helmholtz-Zentrum Geesthacht, Materion GmbH, H.Loitz - Robotik GbR

Description

Gegenstand des Projektes ist die Entwicklung leistungsfähiger Werkzeuge und Fertigungsanlagen für das Rührreibschweißen großflächiger Stahlstrukturen im Dünnblechbereich, mit dem Ziel des wirtschaftlichen Einsatzes dieser innovativen Fügetechnologie im Stahlbereich.

Ausgehend von der Ermittlung der Prozessparameter beim Rührreibschweißen dünnflächiger Stahlstrukturen unter Nutzung von Versuchsanlagen, werden die erforderlichen Anlagen- und Werkzeugparameter bestimmt. Parallel zur Entwicklung neuer Werkzeuge (Werkzeugwerkstoffe, Werkzeugform, Werkzeugoberflächen) werden das Konzept für eine Fertigungsanlage für das Fügen großflächiger Stahlstrukturen im Dickenbereich 3-4 mm erarbeitet, Lösungsvarianten wesentlicher Anlagenkomponenten für das Spannen der Bauteile, die Prozesssteuerung und die Aufnahme des Werkzeuges entwickelt, prototypisch gebaut in die Versuchsanlage integriert und im Labor erprobt.

Im Ergebnis des Vorhabens liegen sowohl leistungsfähige Werkzeuge, als auch ein funktionsfähiges Muster einer Fertigungsanlage vor. Diese bilden die Basis für die nachfolgende Konstruktion, den Bau und die Vermarktung von Fertigungsanlagen für das Rührreibschweißen dünner Stahlbleche.

Research area: Tooling

Contact: M.Sc. Stefanie Hanke

Metal Friction Surface Welding

Project: Ford-University Research Program

Description

The demands on production tools of one car line with approximately 600.000 cars per year over the running period of app. 6 years or more are extremely high. Stamping tools areas with high tool wear are e.g. die radii or draw beads. The use of low cost tool materials with enhanced wear resistance will support both cost reduction and quality improvement. For mild steels, low cost tools like globular grey iron castings (GGG70L or GG25) are used as tool material for stamping tools. Today, coatings are used to reduce wear, which make fast and flexible tool and die changes in production impossible.

Friction Surfacing opens up new possibilities for the repair of worn and damaged components. This process is also potentially useful as an alternative surfacing process as it allows for a compromise between the bulk substrate, which can be dictated by strength or economic constraint, and that of the surface, which can be altered by the application of selective materials to form a protective barrier against wear and corrosion.

The possibility of forming a high quality and regular layer onto a substrate by Friction Surfacing process depends of the selection of appropriate welding parameters. The reproducibility of the weld however, depends of the controllability of the machines used for this purpose.

The Friction Surfacing Process can be divided in two Phases: Pre-heating Phase and Welding Phase. During the Pre-heating stage the rotating stud is pressed onto the substrate, the heat is developed due to the energy generated by friction between the substrate and the rotating stud. The temperature rises just below the melting point of the material, where the yielding strength of the material decreases and the shear stress produced in the stud is high enough to enable plastic deformation in the material.

The welding phase of the process is responsible for the production of the coating layer onto the plate by start of the transversal motion of the rotating rod. In this phase a quasi-steady thermal condition is reached influencing the properties of the HAZ formed. At this point the dimensional properties and the quality of the layer formed are significantly influenced by the transversal speed, rotational speed and the load applied.

When the weld length required is reached, the transversal and rotation motion is stopped and the axial load is maintained, assuring the high bonding quality of the end of the layer.

The projected benefits from this project are cost reduction due to reduced maintenance time and enabling low cost tool material. Further, an improved quality due to reduced tool wear and scratches is expected. The implementation of this advanced technology, which can be used on machines which are already available (milling) with low investment costs is regarded as new solution for well known challenges.

Research area: Tooling

Contact: M.Sc. Stefanie Hanke

Nanocrystalline Composite Coatings with nano textured surface for Cylinder Running Surfaces of highly stressed Gasoline and Diesel Engines - NaCoLab

Project number: 03X0003K

Duration: 01.06.2005 - 31.05.2008

Description

The aim of this research project is to replace grey cast iron liners in aluminium crank cases by a new coating material. By thermal spraying of a newly invented iron based filler wire feedstock alloyed with chromium, carbon and boron a hard, wear resistant and low friction coating is generated. The microstructure of these coating is an amorphous matrix with nanocrystalline precipitates. Increasing pressures during ignition (200 bar and higher) demand coatings which for all that ensure a good reliability and low wear rate.

Within this project a complete, innovative manufacturing chain for coating aluminium crank cases with this nanocrystalline material is developed. It includes the mechanical roughening of the substrate, thermal spraying of the filler wire feedstock and finally the surface finish by honing.

The institute of product engineering, materials science and engineering, advances the furthering of knowledge and understanding of the tribosystem piston ring - cylinder running surface by investigating the acting wear mechanisms. Running-in and wear influence the formation of the lubrication oil film in the contact zone. This results in differing friction losses, emissions and oil consumption which are significantly related to the durability of the motor. Advancing simulation tools to predict running-in and wear within the highly stressed positions top and bottom dead center is an additional objective within this project.

Research area: Automotive

Contact: Dipl.-Ing. Mareike Hahn

Solving Steel Welding Problems by the use of Friction Stir (SOLVSTIR)

Project: funded EU project

Project number: RFS-PR-03077

Description

Conventional fusion welding processes are reaching their applicability limits as far as the weldability of thin gauge, modern high alloy steels (i.e. UHSS, TRIP, CP, MS, DP and IF steels) is concerned. Weldability issues are also a matter of concern in Cr-containing steels employed in the energy sector (i.e. 9Cr1MoNbVN, 12Cr1MoV, etc) due to microstructural control, embitterment and particularly environmental concerns. The Friction Stir Welding (FSW) process, a low heat input, solid state joining method, offers a number of advantages likely overcome weldability problems in difficult-to-weld steel grades. Moreover, FSW has also shown to be able to produce multi-material joints between steel and non-ferrous alloys. Starting from the present state of art in FSW of steels this project intends to focus on two lines of development: process technology and application to relevant steel grades and multi-material joints. The process technology focus will aim at alternative tool materials and geometry, their respective process parameter fields as well as pre- and post-weld heat treatment methods viewing increased tool life and the cost effectiveness of the process. The suitability of the process to different steel grades will be investigated on modern high alloy and Cr-alloyed materials with emphasis on the microstructure development and joint perfromance. This development work will be supported by modelling (temperature and deformation) and by an economic evaluation and concluded with the manufacturing of demonstration structures from the automotive, shipbuilding and energy sectors. In summary, the main objective of this project is to define the merits of FSW when applied to steels based on the achievable joint performance, applicability to structures and economics.

Research area: Tooling

Contact: Dr.-Ing. Christian Zietsch

Reducing the Emission of Wear Debris in Metal on Metal Hip Joints by Means of Microstructured Surfaces

Project: Industrial project

Duration: 01.01.2007 - 31.12.2008

Associate partner: Zimmer GmbH

Description

For years surface texturing is known to be an effective method to improve the properties of certain tribological systems. One approach is to create lubricant reservoirs by non-corresponding dimples in the surface of one of the articulating surfaces. In MEMS devices, surface texturing is used to reduce the contact area in order to overcome adhesion and friction. Another interesting beneficial effect of a textured micro-topography is its function as a wear particle trap. By eliminating particles from the tribological system, third-body-wear is prevented. The metal-on-metal (MOM) artificial hip joint is a system which does not suffer third body wear by means of abrasion. Nevertheless, wear particles are suspected to be responsible for implant failure due to osteolysis, a bone degrading disease that causes implant loosening. A major improvement would be the elimination of wear particles, in particular, during the run-in of the artificial joint. In order to apply a micro-topography different techniques can be performed like machining, ion beam texturing, laser texturing, and etching. For this study an electrochemical etching process is used. The advantage of this process is the homogeneity of the material. Furthermore, this process is a less expensive application than, for example, laser texturing. In order to observe whether an electrochemically textured surface is beneficial for wear performance in a first step, a reciprocating sliding wear test rig has been established. The characterization of the textured surfaces will be performed by means of confocal white light microscopy.

Research area: Biomedical Engineering

Contact: Dipl.-Ing. Robin Pourzal

Microstructure and Deformation Behavior of Coronary Stents under Fatigue

Project: Publicly funded research project

Project number: DFG FI495/9-1, DFG FI495/9-2, DFG WE2671/1-3

Description

Stents are metal vessel scaffolds which are inserted to prevent vessel walls from collapsing. During implantation these stents have to tolerate a distinctly inhomogeneous plastic deformation due to crimping and dilation. Subsequently the implant has to sustain up to 700 million cycles induced by the cyclic diameter change of coronary arteries. During this time biofunctionality as well as biocompatibility have to be guaranteed. Because of the oligocrystalline structure of stents and the type of deformation the structure of the stent undergoes inhomogeneous plastic deformation. This results in local differences in chemical and mechanical load. This research project focuses on the experimental investigation and additional simulation of deformation mechanisms of oligocrystalline stents. Further, the development of a quantitative model for the deformation under static and cyclic load will be established. The diameter of one strut of a stent is generally about 100 µm. Therefore, depending on the grain size, there are not more than five to ten grains within the cross section of a stent strut. Thus the microstructure of only very few or even just one grain can be responsible for the behavior of the entire stent structure. Oligocrystalline structures like stents can in fact neither be described as multi-crystalline materials like fatigue specimens nor can they be treated as single crystals. In crystalline samples a size effect of mechanical properties can be observed if the grain size approaches the dimension of the specimen itself. Therefore mechanical investigations (tension and bending fatigue) are carried out using oligocrystalline wires of commercially used stent materials. The analysis of the deformation behavior will give a more comprehensive understanding of the structure property relationship in such thin structures with focus on the deformation behavior of coronary stents. The present study will help to develop a model based on experimental data to reach a better prediction for the endurance of coronary stents.

Forschungsbereich: Biomedical Technology

Ansprechpartner: Priv.-Doz. Dr.-Ing. Sabine Weiß