Forschungsberichte

Forschungsberichte

Early Career Researcher gewähren uns einen Einblick in ihre aktuellen Forschungsprojekte und stellen die Arbeiten einzelner Fachgebiete bzw. Arbeitsgruppen vor. So tragen wir die Forschung nach außen und generieren mehr Sichtbarkeit innerhalb der Fakultät und nach außen. Zusätzlich wird der Beitrag über den LinkedIn-Account der Fakultät veröffentlicht.

Falls Sie auch Ihre Forschung hier abbilden möchten, melden Sie sich bitte per E-Mail an die Forschungskoordinatorin

Dr. Miriam Böhm (miriam.boehm@uni-due.de)

The Power of Simulations: Advancing Magnetic Materials for Renewable Energy

Dr. Maximilian Vorwerk & Dr. Jörg Schröder

The Power of Simulations: Advancing Magnetic Materials for Renewable Energy - Dr. Maximilian Vorwerk & Dr. Jörg Schröder

Figure 1: a)-d) and f)-i) polycrystalline hard magnetic microstructure under alternating external

magnetic field H_3 and magnetization vectors m, and e) effective hysteresis loop. For details see

data publication [15].

Magnetic materials play a crucial role in the expansion of renewable energy. They are key components in energy-converting applications such as wind turbines and electric vehicles. However, a major challenge arises from their reliance on rare earth elements (REEs). Although REEs are not geologically scarce, their extraction is subject to environmentally harmful processes. Moreover, unrestricted access is not fully guaranteed due to geopolitical tensions. To address these challenges, it is vital to optimize resource utilization and push the performance boundaries of magnetic materials through targeted research into optimized microstructures and chemical compositions. The transregional Collaborative Research Center 270 (CRC TRR 270) "HoMMage" is dedicated to advancing the capabilities of magnetic materials. It is a joint effort of Technische Universität Darmstadt, Universität Duisburg-Essen, Bergische Universität Wuppertal, Max Planck Institute for Sustainable Materials and Ernst Ruska-Centre for Microscopy and Spectroscopy with Electrons (ER-C) at Forschungszentrum Jülich, bringing together an interdisciplinary team of researchers from materials science, physics, chemistry, and engineering. Across 29 distinct projects, scientists work collaboratively to explore new frontiers in magnet performance. Experimental studies on magnetic materials can be time-consuming and expensive, often requiring high precision to capture transient phenomena. This is where in-silico characterizations come into play. Using finite element methods, we solve differential equations to predict the behavior of magnetic materials and optimize processing parameters. High-resolution modeling is necessary for accurate predictions, leading to immense computational demands. To manage this, parallel computing across multiple cores of high-performance computing (HPC) clusters, such as Magnitude or Amplitude, is indispensable. Through advanced simulations and interdisciplinary collaboration, our research is shaping the future of sustainable magnetic materials, contributing to a more resilient and efficient renewable energy landscape.

About the working group:

The work of the Institute of Mechanics focuses on theoretical and computer-oriented mechanics. The focus is on material science questions and the enhancement of the finite element method. A variety of simulation tools are used for this purpose, such as (multi-)phase field models, single-scale as well as multi-scale finite element models. In this context, computationally complex large-scale simulations play a major role. This led to Prof. Dr. Jörg Schröder playing a leading role in the application for the new computing cluster amplitUDE as the main applicant.

Q&A

What is your favorite experiment/part of your daily work?

It is incredibly exciting to deal with complex issues, reduce them to fundamental problems, analyze them in a targeted manner and achieve a concrete solution in the end.

What do you enjoy most about your research in general at the faculty of engineering/or the UDE?

Above all, it is the interdisciplinary exchange with colleagues from other departments and the joint search for customized solutions to emerging issues. The main opportunities, but also challenges, lie in the different approaches to solution processes. There is only one physics, but many ways to communicate about it.

Is there something you are looking for? Like an expert for a specific method, critical feedback or a collaboration partner?

New collaborations from different areas are always welcome and can be discussed in more detail over a coffee.

How does #amplitUDE boosts your research?

The newly available computing power, provided by the amplitUDE, is the boost for my simulations and thus my scientific output.

Contact

Unlocking the Power of Residual Stresses – Dr. Sonja Hellebrand

Left: Investigated cylindrical specimen with initial and final dimensions.

Right: Macroscopic stress distribution and microscopic simulations results regarding stresses and phase evolution.

Steel is one of the most important materials in engineering but to meet modern requirements, it is of great importance to induce special properties. A decisive influencing factor for component optimization are residual stresses that can be induced during manufacturing. Generally, residual stresses are the stresses in a body that remain in absence of outer forces and are characterized based on the scale they act on into three different types, which can be roughly divided into macroscopic (1st type) and microscopic (2nd and 3rd type) residual stresses. Instead of minimizing residual stresses in metallic components to avoid possible negative impact regarding the components’ performance, we aim for the targeted use of forming-induced residual stresses to increase propertiessuch as the fatigue strength or wear resistance. Here, focus lies on the induction of compressive residual stresses in surface near regions in a hot bulk forming specimen. Therefore, the key aspect isthe combination of numerical and experimental tools, wherein especially multiscale simulation models offer great potential to test promising process routes cost-effectively while at the same time including macro-and microscopic material characteristics. By combining experiments, single finite element (FE) and multiscale finite element simulation (FE²) tools, the goal is to induce and adapt residual stresses in a targeted manner during the manufacturing process and to show the stability of these stress states to improve the component’s properties verifiable.

About the working group:

Numerical simulation and the associated analysis of various processes play a major role at the institute. A variety of simulation tools are used for this purpose, such as (multi-)phase field models, single-scale as well as multi-scale finite element models. This allows a wide range of highly interesting topics to be investigated. Thus, we devote ourselves to a large number of research areas: multi-scale simulations, coupled problems, particularly of an electro-magnetic nature, but also develop new finite element approaches.

Q&A

What is your favourite part of your daily work?

I like coming together with so many different people and backgrounds to discuss a research problem. The lively exchange is a lot of fun and at the same time offers many new possibilities through the great variety of perspectives and thoughts. It's also exciting to learn something new every day and to carry out diverse tasks.

What do you enjoy most about your research in general at the faculty of engineering/or the UDE?

I really appreciate the possibilities at my institute but also in the whole faculty. There is always the opportunity and encouragement to participate in research-related or carrier-related training.

Is there something you are looking for? Like an expert for a specific method, critical feedback or a collaboration partner?

Feedback is always welcome to improve our project work. Moreover, it would be great to find someone (maybe you?) to continue the work on related topics.

How does #amplitUDE boosts your research?

#amplitUDE is a key aspect in this research area. Multi-scale simulations are on a par with high numerical costs and long running times so that such analyses can not be performed on single computers nowadays. Therefore, such HPC clusters are essential to carry out my research work.

Contact

Engineering Mathematics – Dr. Elodie Donval

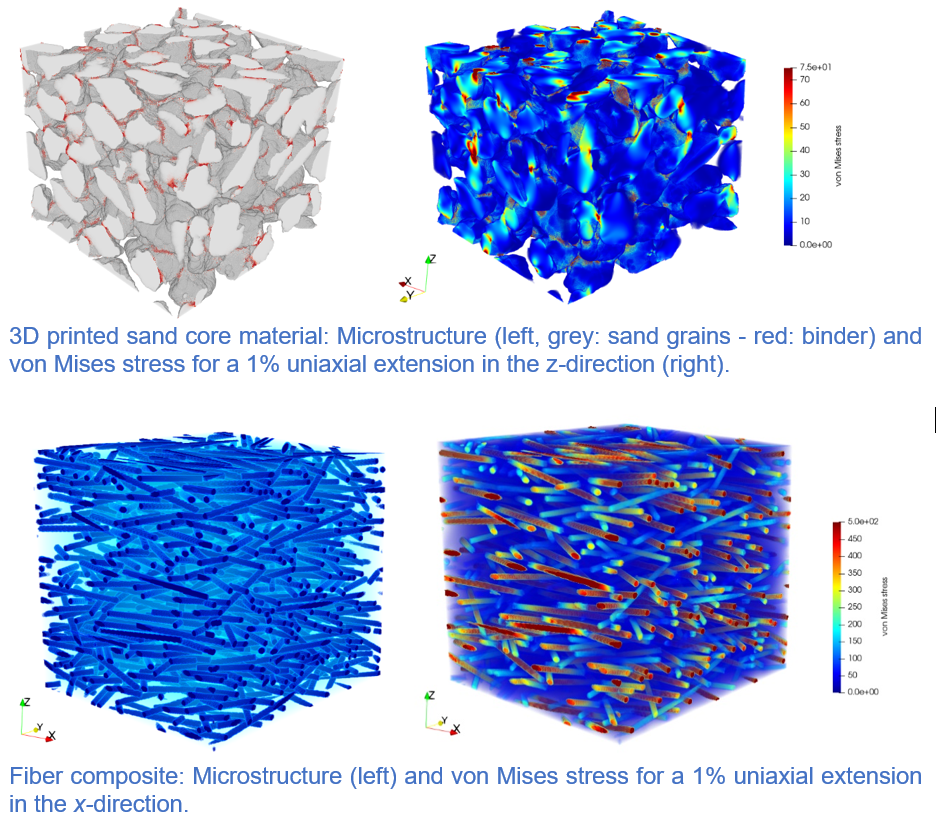

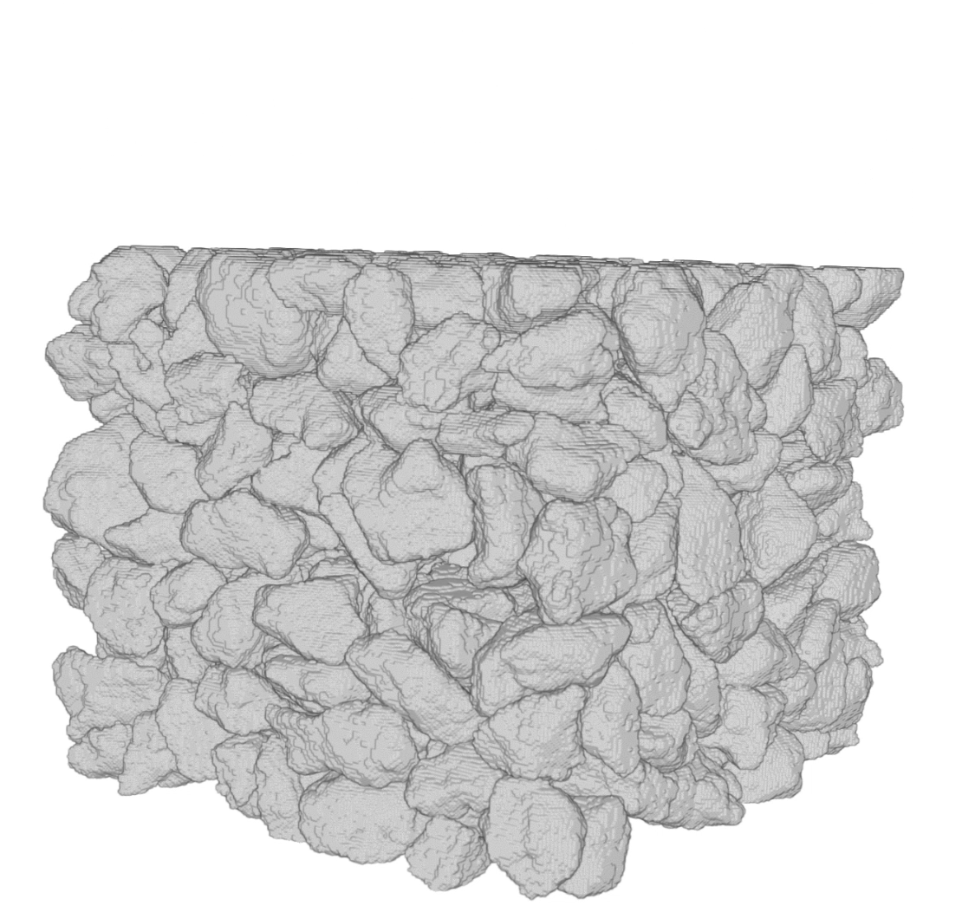

My current research project focuses on a better understanding of the mechanical properties of inorganic 3D printed sand cores for foundry applications. In this DFG-funded project, we are working closely with project partners to better understand the thermo-mechanical behaviour of the 3D printed material from an experimental and numerical point of view. My role in this project is to investigate the arrangement of sand and binder at the microscopic scale from a computational point of view.

Microstructure modelling

It is not always possible to collect CT scan data to understand the microscopic behaviour of composites. In such a case, computationally generated microstructures provide a convenient solution. In this project, we propose methods to model the arrangement of sand grains as they are deposited layer by layer in the 3D printing process and binder addition. This microstructure generation tool allows us to perform parametric studies and try to understand what the optimal printing parameters are.

Computing material properties

Once the microstructure is generated, we aim to evaluate the macroscopic behaviour of the printed material through computational FFT-based homogenization. The goal is to better understand the material and assess whether it has the required properties, particularly in terms of permeability and strength, to be used for casting. In this case, this is particularly challenging as we are looking at porous microstructures. We are therefore also developing efficient homogenization solvers.

About the working group:

Microstructure generation and computational homogenization are among the main topics of interest at the institute. On the microstructure generation side, we mainly work on industrial microstructures, composed of fibers for instance. Regarding computational, FFT-based homogenization, some of the questions we are addressing include: How can we improve the accuracy and computational time? Is it a good idea to perform the computation directly on the CT scan data, and if so, how? What can we do to better describe the failure at the microscopic level and what does it mean at the macroscopic level? By understanding composite materials at the microscopic scale, we hope to provide clues for to model them at the macroscopic scale. If you are interested in these questions too, the institute provides Master-level courses on these topics. We also offer Bachelor and Master thesis, feel free to reach out!

Q&A

What is your favourite experiment/research in general?

What I really like about my research is to understand how tiny changes in the microstructure can affect the global behavior of a whole element (a mold for my current project). By understanding that, it paves the way to optimizing the microstructure.

What do you enjoy most about your research in general at the faculty of engineering/or the UDE?

I am working in a great team at the Institute, and I think that’s the most important! However, one thing which is very specific to UDE and that I really enjoy as a postdoc is all the training opportunities about research-related skills and career development that are offered by the Graduate Research Center and the Research Academy Ruhr.

Is there something you are looking for? Like an expert for a specific method, critical feedback or a collaboration partner?

We would be very happy to find experimental collaboration partners interested in computational modelling of composite materials!

Contact

Metallurgy of Iron- and Steel-Production – Philipp Winstermann

Hydrogen plays a central role in the path to decarbonization. As a fuel or process gas, hydrogen releases no carbon-containing or other harmful emissions when used. The different temporal and geographical availability of renewable energies for producing green hydrogen highlights the necessity of storage and transportation options. This challenge is addressed by the Me2H2 project. The iron-steam process is to be established as an alternative to liquefaction, conversion to ammonia, or binding in hydrocarbons. The energy of the hydrogen can be stored by reducing suitable metal oxides based on iron. At the time and place of demand the energy stored in the iron material can be released again in the form of hydrogen through the iron-steam process. In this process, the material is oxidized with the help of steam, which reacts to form hydrogen. This process was already used industrially to produce hydrogen at the beginning of the 20th century and is thus proven on a large scale. Advantages include the avoidance of the "boil-off effect" of liquefied hydrogen and the toxicological safety compared to ammonia or liquid hydrocarbon carriers. Together with partners at the TU Clausthal, the Leibniz Institute for Materials-Oriented Technologies, thyssenkrupp SE, and the SMS Group, we are identifying suitable material systems, dealing with fundamental questions and developing the associated process and plant technology. Many thanks also to Rahmatika Islamia and Kesytlanang Tristanav W, two bachelor candidates that are currently working with Philipp under the double degree program!

About the working group:

The research area of metallurgy is primarily concerned with thermodynamic and kinetic investigations of liquid metal phases, metal/slag reactions, issues relating to the solidification of metals and the recycling of oxide and metallic residues (filter dusts, slags). To this end, research and teaching focuses on the characteristic properties of a wide range of metallic materials, including steel and cast iron as well as light and non-ferrous metals.

Q&A

What is your favourite experiment/research in general?

The experiment that works of course!

What do you enjoy most about your research in general at the faculty of engineering/or the UDE?

That our motto “open-minded” is lived out. New ideas are appreciated as there is a lot of room to gain experiences and test different scientific approaches.

Is there something you are looking for? Like an expert for a specific method, critical feedback or a collaboration partner?

I am open to network, especially in the field of hydrogen storage and transport.

Contact

Maschinenbau und Verfahrenstechnik

Institut für Technologien der Metalle (ITM)

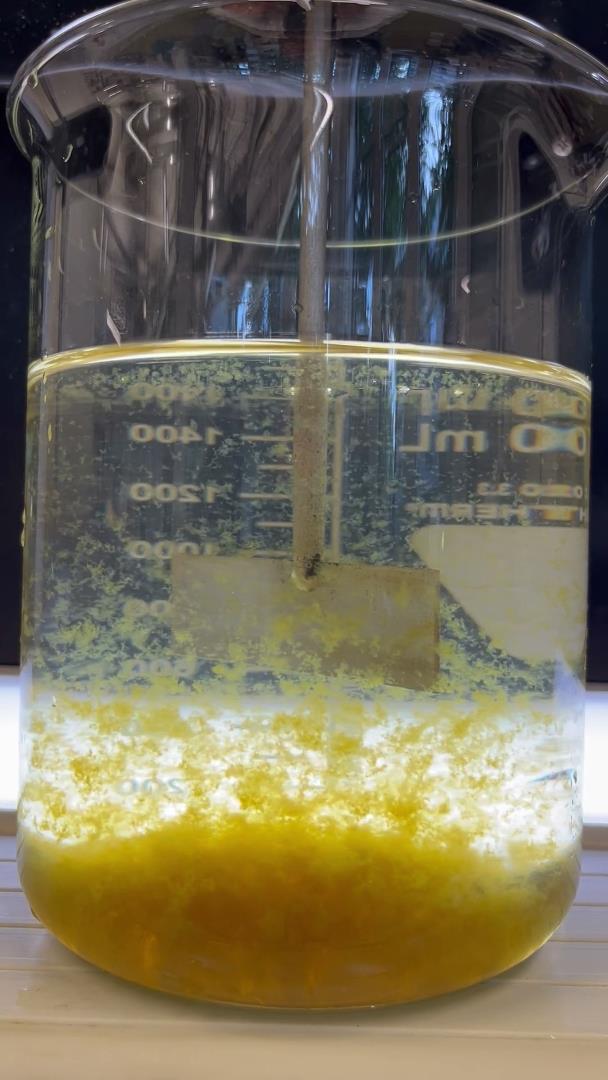

Process Engineering / Water Technology – Marko Schiele

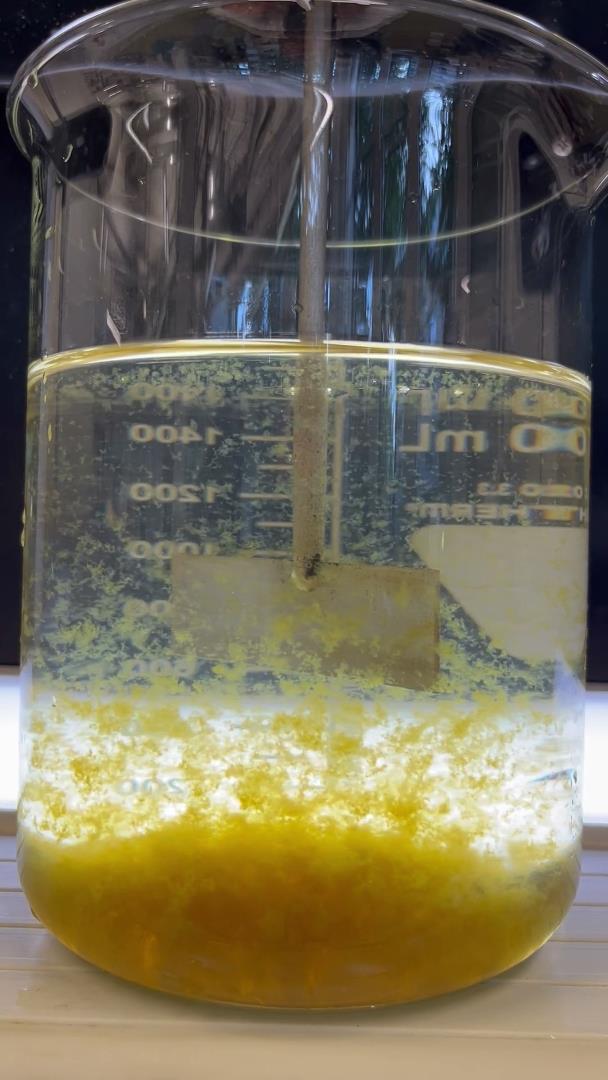

Water appears in various forms, such as groundwater from the soil, surface water from rivers and lakes, or spring water. In most cases, direct consumption is not entirely safe due to pollutants or microbial health risks. Coagulation and flocculation are water treatment processes that destabilize and agglomerate suspended particles to form larger, settleable flocs that can be removed by sedimentation or filtration. Being one of the first steps in the treatment chain, especially for surface waters, the coagulation process is nowadays almost exclusively relying on metal-based coagulants such as iron or aluminum, often in combination with synthetic organic polymers. The project ‘”Nature Floc” is aiming at a more eco-friendly coagulation process. We characterize, compare and test coagulants on base of natural raw materials such as starch or chitosan (a polymer derived from the shells of shrimps). Algae-based substances also show potential. The comparison of flocculants through flocculation tests is the exciting part of the project. Practical lab experiments are always fascinating, and in flocculation tests, they are also highly visual, making it immediately clear whether changes in parameters had a positive or negative effect. The overarching goal of the project is to obtain legal approval for natural flocculants in water treatment in Germany. Through our research work, we can truly make a difference!

Über die Arbeitsgruppe:

Um die nationalen und internationalen Herausforderungen im Bereich der Wasserversorgung zu adressieren, werden am Lehrstuhl MVT/WT mit den Schlüsselkompetenzen Membranfiltration und Adsorption schwerpunktmäßig die drei Forschungsfelder

Erschließung belasteter Wasserressourcen

Prozessoptimierung und -simulation

Kreislaufwirtschaft

bearbeitet. Konkrete Themen in laufenden Projekten sind die weitergehende Aufbereitung von Kläranlagenabläufen, die Wiederverwendung hypersalzhaltiger Abwässer sowie die Nutzbarmachung stark verschmutzter Wasserressourcen (z.B. ölhaltige Abwässer oder eutrophe bzw. stark algenhaltige Wässer). Schwerpunkte bei der Prozessoptimierung und –simulation liegen auf integrierten Membransystemen und Hybrid-Membranprozessen sowohl mit keramischen als auch mit polymeren Membranen. Im Forschungsfeld Kreislaufwirtschaft werden umweltfreundliche und regenerative Materialien und Betriebsstoffe für die Wasseraufbereitung erforscht, dazu zählt auch die Vermeidung oder Nutzbarmachung von Rest- und Abfallstoffen.

Q&A

What is your favorite experiment/part of your daily work?

My favorite part of the day is conducting my lab experiments. My favorite experiment is the flocculation test or „Jar-Test“, where the flocculant is added to the contaminated water under continuous stirring to start the flocculation process. I like that this experiment gives direct insights into how well the flocculation works based on the set parameters.

What do you enjoy most about your research in general at the Faculty of Engineering or the University of Duisburg-Essen (UDE)?

First of all, I appreciate that the faculty’s research addresses real future challenges and thus has a positive impact on water treatment. I also enjoy having the freedom to explore my own project while receiving extensive support in improving myself and growing through the Project.

Is there something you are looking for? Like an expert for a specific method, critical feedback or a collaboration partner?

The project is still in its early stages, and we have reliable partners by our side who support us with their specialized expertise.

Contact

Maschinenbau und Verfahrenstechnik

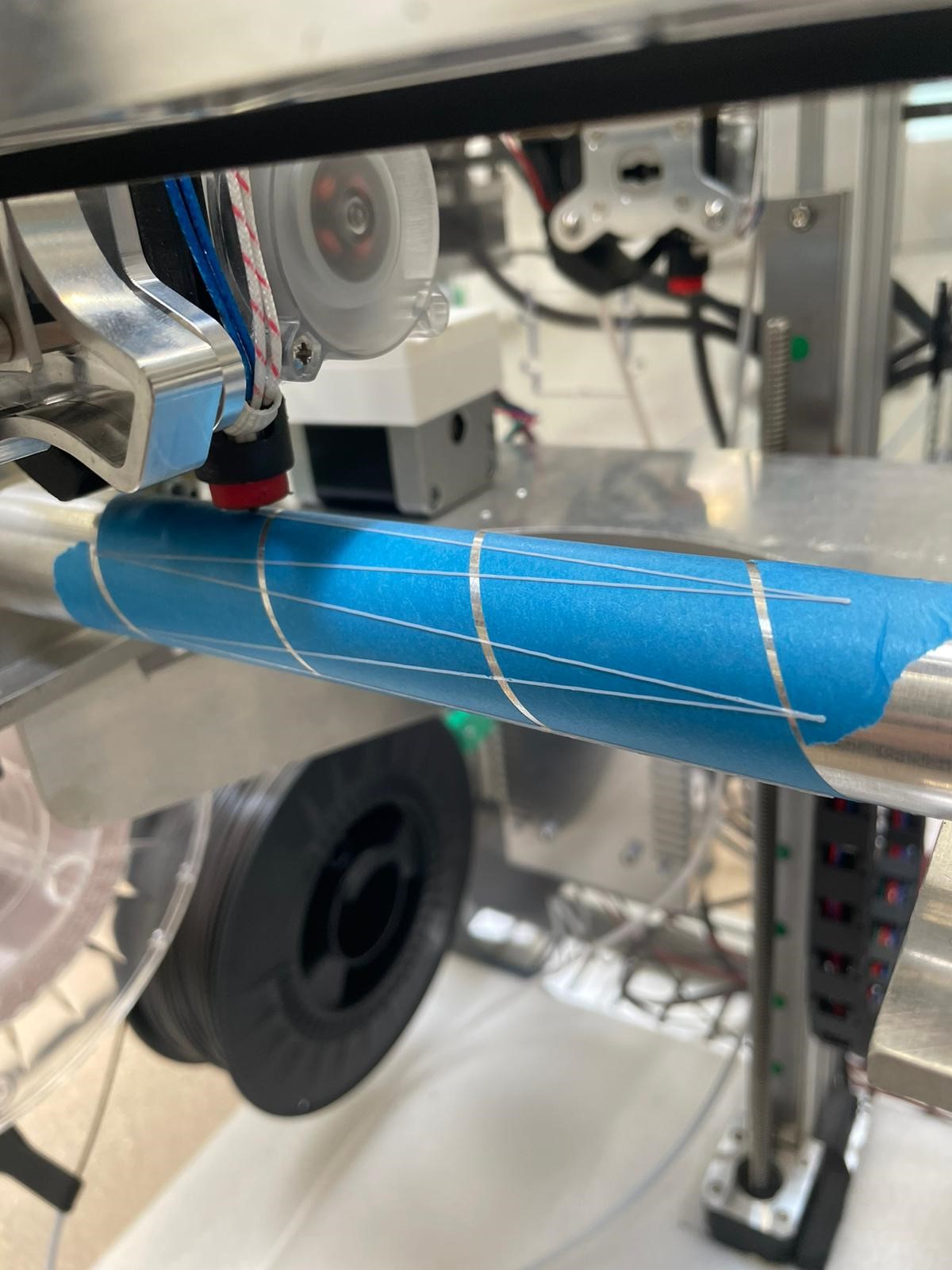

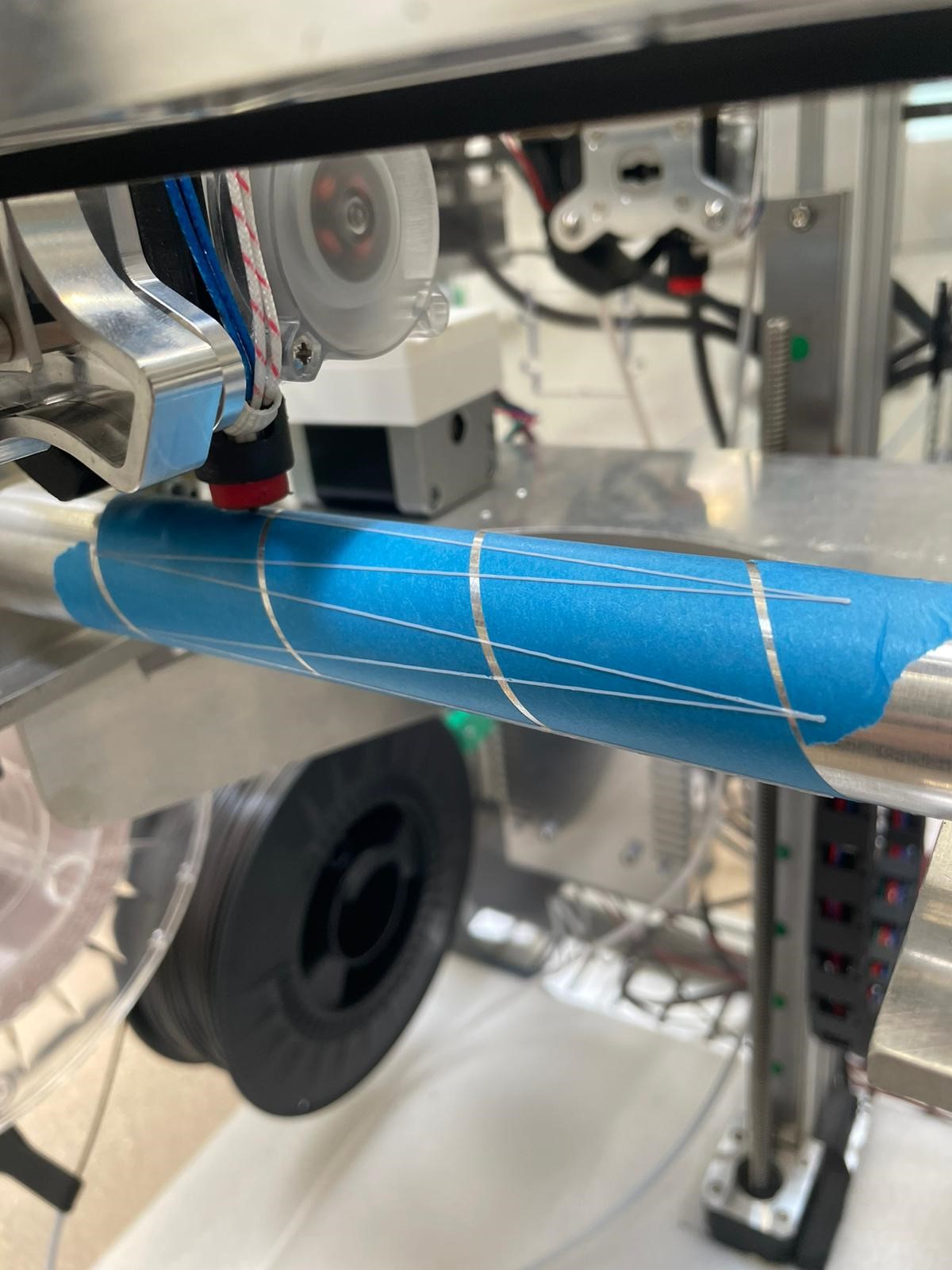

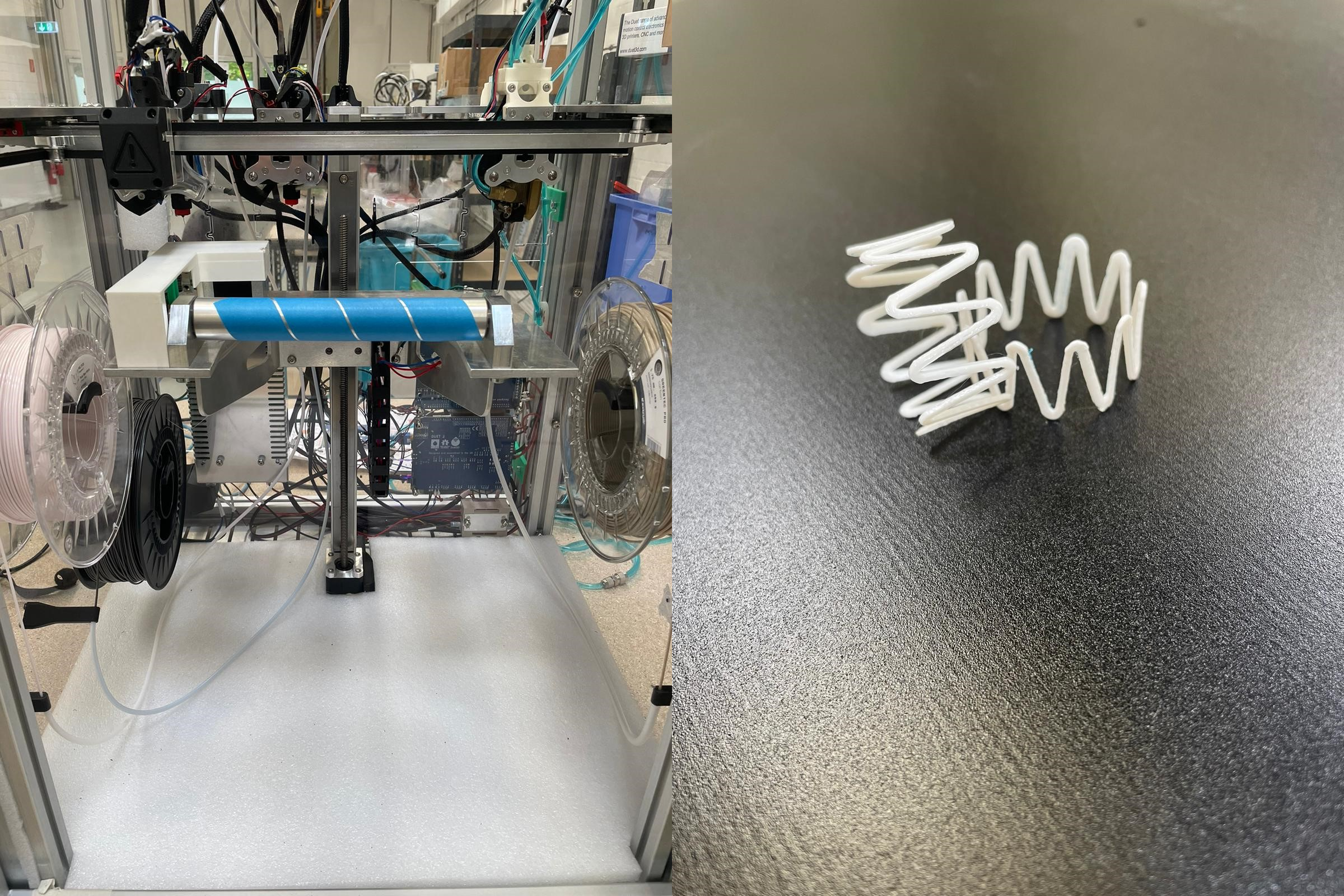

Additive Fertigungstechnik – Marius Meyer

Bei der Reparatur von Aortenaneurysmen, also Vergrößerungen der Hauptschlagader, kommen sogenannte Stentgrafts zum Einsatz. Hierbei handelt es sich um eine stabilisierende Gefäßprothese, die üblicherweise aus einem Kunststoffgewebe besteht, in das ein Drahtgeflecht aus Metall eingenäht ist. Während das Gewebe, also der Graft, die Funktion des Gefäßes übernehmen soll, sorgt die Stentstruktur aus Metall für die mechanische Stabilität und die Befestigung in der Aorta. Die Implantation solcher Stentgrafts erfolgt unter Einsatz von Röntgenstrahlung über die Oberschenkelarterien. Dieser Vorgang ist mit einer entsprechenden Strahlenbelastung verbunden, sowohl für medizinisches Personal als auch behandelte Personen. Das BMBF-geförderte Verbundprojekt MEVAR hat zum Ziel, Stentgrafts aus einem Polymer herzustellen, das im MRT sichtbar ist, um die Strahlenbelastung zu minimieren und den aktuell sehr kostspieligen und größtenteils manuell ablaufenden Fertigungsprozess mittels Kunststoff-3D-Druck zu automatisieren. Hierzu wird am Lehrstuhl für Fertigungstechnik eine Hochtemperatur-Materialextrusionsanlage entwickelt, mit welcher der Druck von schlauchförmigen Bauteilen aus speziell für diesen Prozess zu entwickelnden, biokompatiblen Hochleistungspolymeren möglich ist. In dieser Anlage wird die Stentstruktur über ein rotatorisches Druckbett direkt auf den Graft aufgedruckt, sodass kein manuelles Nacharbeiten mehr notwendig ist.

Über die Arbeitsgruppe:

Im Mittelpunkt der langjährigen Aktivitäten im Bereich der Rapid Technologien stehen dabei stets aktuelle Probleme auf dem Weg zum Rapid Manufacturing wie beispielsweise die Qualifizierung neuer Materialien, das tiefgehende Prozessverständnis, die RM-gerechte Konstruktion oder die Entwicklung von medizinischen Instrumenten. Alle Forschungsaktivitäten auf dem Gebiet der werkzeuglosen Fertigung werden am Lehrstuhl im Rapid Technology Center (RTC) gebündelt. Im Bereich der Montagetechnik beschäftigt man sich vornehmlich mit dem Integrieren von hybriden Systemen zur Flexibilisierung der Prozesse, mit der Optimierung manueller Arbeitsprozesse hinsichtlich Ergonomie und Gestaltung, sowie mit Simulationen in der Montage. Für die Zusammenführung der Forschungsvorhaben auf dem Gebiet der Montagetechnik existiert am Lehrstuhl Fertigungstechnik das Labor für Montage und Simulation „HYBRID PROCESS“.

Q&A

What is your favourite experiment/research in general?

DSC (Differential Scanning Calorimetry, dt. Dynamische Differenzkalorimetrie), weil sie Auskunft darüber gibt, welches thermische Verarbeitungsfenster ein Material hat, die Vorbereitung der Proben ein wenig Fingerspitzengefühl erfordert und die Messungen größtenteils von allein ablaufen.

What do you enjoy most about your research in general at the faculty of engineering/or the UDE?

Die Möglichkeit zur Mitgestaltung des eigenen wissenschaftlichen Werdegangs über die Akquise von Folgeprojekten, sodass man nicht nur innerhalb seines ursprünglichen Fachgebiets bleiben muss, sondern die Arbeit auch selbstständig in eine gewünschte Richtung lenken kann.

Is there something you are looking for? Like an expert for a specific method, critical feedback or a collaboration partner?

Aktuell suche ich hauptsächlich nach möglichen Kooperationen für Folgeprojekte zur Weiterentwicklung und Untersuchung des (Kunststoff)-3D-Drucks. Die für mich interessantesten Bereiche sind hier Materialextrusion auf Textilien, gedruckte Verbundsysteme (insb. für orthopädische/medizinische Anwendung) und Kunststoff-/Werkstofftechnik.

Contact

Maschinenbau und Verfahrenstechnik

Institut für Produkt Engineering

Energy Technology – District Heating - Joana Verheyen

District heating systems (DHS) are a cornerstone of urban energy infrastructure, distributing heat through networks that supply residential, commercial, and industrial buildings. Traditionally these centralized systems are powered by fossil fuels and need to be transformed through the integration of renewable heat suppliers and waste heat. Within the research project TeoS*, we at the Chair of Energy Technology are working with our partners, the district heating network operators BTB GmbH Berlin and Fernwärme Duisburg GmbH, on how such networks can be supplied in the most climate-friendly way possible. First, the project partners' data will be collected and processed in order to develop models for the energy conversion plants, thermal energy storage and distribution grids. Taking into account characteristic meteorological years as well as price and heat demand profiles, the future scenarios are then calculated, checked for plausibility and evaluated from a technical, economic and ecological point of view. The combination of optimized system operation (unit commitment problem) and hydraulic network calculation is an important goal here, as challenges such as lower temperature levels or fluctuating availability arise from the integration of sustainable energy sources such as large heat pumps (river water, waste water, waste heat), deep geothermal energy, industrial waste heat, and solar thermal energy. To reduce the mismatch between availability and demand, both short-term and seasonal thermal energy storage systems are considered. *"Technology-Open Energy System Analysis for the Derivation of Measures for the Decarbonization of Urban Heating Networks" ("Technologieoffene Energiesystemanalyse zur Ableitung von Handlungsmaßnahmen für die Dekarbonisierung urbaner Wärmenetze"), research grant no. 03EI1060A, funded by Germany’s Federal Ministry for Economic Affairs and Climate Action

Über die Arbeitsgruppe:

The Chair of Energy Technology (LET) conducts experimental and simulative research in the field of electrochemical energy converters as well as in the field of rational energy use and energy conversion with a focus on CHP, renewable heat and district heating. Specifically, the design, processes and possible applications of batteries (zinc-polyiodide, nickel-zinc, zinc-manganese, lithium-ion), fuel cells and renewable energy sources (hydrogen, ammonia) are being intensively researched. In the field of rational use of energy, several software tools have been developed for the calculation and evaluation of energy conversion systems (conventional and renewable), thermal energy storage, optimal plant operation and thermo-hydraulic modeling of district heating networks. The work will be further exploited by the affiliated institute that emerged from the chair, the Center for Fuel Cell Technology (ZBT), and the young spin-off Lagom.Energy GmbH.

Q&A

What is your favorite experiment/part of your daily work?

Discussing the energy of the future is a constant reminder of how little we really know - so there is always a lot to learn! And sometimes I completely lose time while programming, which can be very nice when you find your error...

What do you enjoy most about your research in general at the faculty of engineering/or the UDE?

I have the pleasure of getting to know many different people and at the same time developing my research questions in a collegial and interesting working group.

Is there something you are looking for? Like an expert for a specific method, critical feedback or a collaboration partner?

If you have already dealt with multi-criteria optimization in Python/Gurobi, I am very interested, as I would like to apply this to our energy system simulations. Otherwise, I am also happy about other kind exchange.

Contact

Maschinenbau und Verfahrenstechnik

Institut für Nachhaltige und Autonome Maritime Systeme (INAM) - Mehrskalige Kavitation

Prof. Bettar O. el Moctar

Institut für Nachhaltige und Autonome Maritime Systeme (INAM) – Mehrskalige Kavitation - Prof. Bettar O. el Moctar

Simulation von mehrskaligen kavitierenden Strömungen in Wechselwirkung mit Strukturen

Kavitation bezeichnet das Druck-getriebene Anwachsen und Kollabieren von Dampfblasen in einer Flüssigkeit. Unterschreitet der Druck in einer Strömung den Sättigungsdampfdruck, so kommt es zum Wachstum von nicht-kondensierbaren Gasblasen zu Kavitationsblasen. Nimmt der Druck in der Strömung zu, kollabieren diese Kavitationsblasen und emittieren dabei ihrerseits Drücke in der Größenordnung von Gigapascal. Kavitation ist in den meisten Fällen eine unerwünschte Erscheinung, sie spielt in vielen technischen Bereichen eine wichtige Rolle. Im maritimen Kontext ist Kavitation bekannt durch ihre erosive Wirkung, induzierte Vibrationen und Schallabstrahlungen. Am Institut für Nachhaltige und Autonome Maritime Systeme (INAM) werden kavitierenden Strömungen auf Nanobis Makroskalen simuliert. So wird der Kollaps von Nanoblasen in der Nähe von Strukturen basierend auf einem Molekulardynamik-Modell (MD) simuliert, um die Blasendynamik auf molekularer Ebene abzubilden, die Bildung von Kavitationskeimen zu verstehen, den Phasenwechsel zwischen Flüssigkeit und Gas zu untersuchen und die Auswirkung auf Werkstoffe nachzuvollziehen. Auf Meso- und makroskalige Strömungen werden basierend auf der Lösung von Navier-Stokes-Gleichungen simuliert. Dabei werden zum einen die Flüssig- als auch die Gasphasen als Kontinua modeliiert. Zum anderen entwickeln wir mehrskalige Euler-Lagrange-Verfahren, die die Simulation einzelner, sphärischer Kavitationsblasen mit der Simulation makroskaliger technischer Strömungen kombinieren.Über die Arbeitsgruppe:

Das Institut für Nachhaltige und Autonome Maritime Systeme (INAM) befasst sich schon seit Jahrzehnten mit der Entwicklung maritimer Systeme auf verschiedenen Skalen, sowohl in der Grundlagen- als auch der angewandten Forschung. Hier spielt das Thema Nachhaltigkeit eine zentrale Rolle, da wir mit unseren Entwicklungen anstreben, den Energiebedarf maritimer Systeme zu reduzieren oder die Leistungsfähigkeit der Systeme bei gleichem Energiebedarf zu erhöhen. Außerdem bearbeiten wir eine Reihe von Projekten, die sich mit der Automatisierung der Schifffahrt befassen. Auch Themengebiete, die sich mit der Aerodynamik von Luftfahrzeugen befassen, sind Gegenstand der Forschung am INAM. Bei allen Forschungsaktivitäten streben wir einen zügigen Transfer der Forschungserkenntnisse in die Ausbildung unserer Studierenden sowie in die maritime Wirtschaft an.

Contact

Maschinenbau und Verfahrenstechnik

Referenzen:

Rezaee, S., Kadivar, E., el Moctar, O. (2024). The role of sawtooth-shaped nano riblets on nanobubble dynamics and collapse-induced erosion near solid boundary. Journal of Molecular Liquids, vol. 405, 2024, 124947

Peters, A., el Moctar, O. (2020). Numerical Assessment of Cavitation-Induced Erosion Using a MultiScale Euler-Lagrange Method Journal of Fluid Mechanics, vol. 894.

Sagar, H.J., Lin, Y., el Moctar, O. (2024). Dynamics of a single cavitation bubble near an oscillating boundary. Scientific Reports 14, 22031 (2024).